Introduction of MRHS

The function of Mill Reject Handling system (MRHS) is to automatically discharge the iron pyrite and other non‐grind‐able material from coal mill through an outlet connection to the reject conveying system.

Basic Working of Mill Reject Handling System (MRHS)

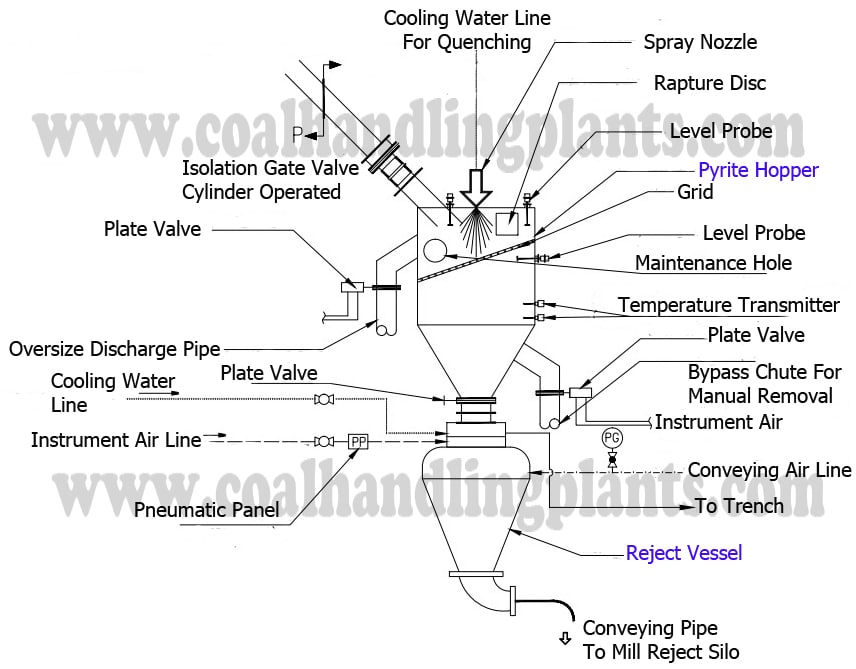

Mill rejects will be led to respective pyrite hopper through mill rejects outlet spout and thereafter, it is further discharged to the transport vessel. Pneumatic conveying system has been envisaged for conveying of rejects from the transport vessel to mill reject silo.

System Description of MRHS

Mill reject handling system (MRHS) consist of Following sub system or equipment:

1. Conveying Air System

Conveying air compressor will located in plant compressor house to supply compressed air required for mill rejects conveying.

2. Instrument Air System

For actuation and process air requirement in the system, instrument air will be provided at each stream through plant distribution instrument air pipe network from the specified tapping point to the pneumatic cylinder operated plate vales, bag filters, transport vessel and panels.

3. Cooling & Spray Water System

Necessary cooling water pipelines will be provided for cooling water requirements in dome valves and for quenching of mill rejects in pyrite hopper, whenever the temperature of the pyrite hopper exceeds desired levels. Service Water will be used for Quenching & Dome Cooling purpose. However cooling water requirement for conveying air compressor will be cater by DMCW water.

4. Pyrite Hopper

The pyrite hopper will be provided with one pneumatic cylinder operated plate valve on upstream which will be normally kept in open position. Grid will be provided in the hopper to prevent passage of oversize material to mill reject vessel.

One chain/manual operated plate valve will be provided to remove rejects collected on the grid manually. Pyrite hopper will be provided with bypass chute with cylinder operated plate type valve to unload the pyrite hoppers on the ground in case of emergency.

Pyrite hopper will be provided with manual operated plate valve on downstream side which is normally kept in open position, as it is a maintenance valve. Pyrite hopper will be provided with level probes and RTD. RF type level probe in the Pyrite hopper will pick up the signal when the hopper is full to a preset level. Arrangement of nozzles to spray water by operating the solenoid valve in the spray water line will be provided when temperature goes beyond the preset value.

5. Mill Reject Vessel / Transport Vessel

One mill reject vessel will be provided for each pyrite hopper to transport mill rejects to storage bunker by means of dense phase conveying system.

Level probe in Pyrite hopper is set to pick up the signal when mill rejects reach a preset level in the hopper. Whenever such a signal is picked up by the probe, the inlet/ material handling valve is actuated to open and allow gravity feed of rejects into the Reject/transport vessel.

After lapse of predetermined time, the material handling/inlet valve closes and compressed air is injected through air inlet valve and the vessel gets pressurized. At predetermined pressure, the outlet valve of reject/transport vessel opens and rejects are conveyed to reject silo/storage bunker through pipeline.

As evacuation proceeds, vessel pressure drops and at a predetermined pressure, air inlet valve and outlet valve closes and the system gets ready for the next batch evacuation, commencement of which is signaled by level probe in the pyrite hopper.

This cycle goes on repeat with convey of mill rejects continuing till high level is sensed in the reject silo/storage bunker.

6. Reject Silo / Storage Bunker

The reject silo/storage bunker will be provided with adequately sized bag filter to vent the transport air to atmosphere, terminal boxes, level probe, Level Transmitter and pressure relief valve on the top of storage bunker. Manual operated discharge gate will be provided at outlet of storage bunker to unload the rejects into trucks. Clear height for truck shall be approx. 4.5 meter is provided.

Operation Philosophy of Mill Reject Handling System (MRHS)

The pneumatic cylinder operated plate valve at mill outlet (Pyrite Hopper inlet) is normally kept open. Mill Rejects from coal mill will drop into the Pyrite Hopper through the grid. Oversize material will be retained on the grid. A pneumatic cylinder operated Plate Valve on oversize material discharge chute will be provided, which will be operated automatically in case of accumulation of oversized rejects.

Mill outlet valve will be closed when oversized rejects discharge outlet is opened. The High Level probe with switch in Pyrite Hopper will pick up when Pyrite Hopper is full or grid is choked. The emergency bypass chute will be fitted with a pneumatically operated plate valve and will be opened in case of emergency only.

Whenever the bypass valve is opened, it will be ensured that the Pyrite Hopper inlet valve is closed. The manually operated plate valve at Pyrite Hopper outlet will normally be kept in open position and will be closed for maintenance purpose only.

Each pneumatic cylinder operated Plate valve/gate valve of Pyrite Hopper shall be provided with open & close limit switch for indication in local and in OWS of DDCMIS. RTD with Temperature Transmitter in Pyrite Hopper will be provided, which will be set to generate annunciation in case the temperature goes beyond the set value and to open the Solenoid Valve in Spray Water line to spray water into the hopper.

In addition to probe mode, the quenching operation will also be provided with timer control. During normal operation, the Solenoid Valve on spray water line (normally closed) will be opened whenever dome valve is opened and water will be sprayed for quenching mill rejects in Pyrite Hopper for a short duration (adjustable between 5 to 10 Seconds).

Dome valve top plate will be provided with continuous cooling water supply to protect the insert seal through cooling water system sourced from service water system. Level probe with switch in Pyrite Hopper will be provided, which will be set to pick up when the mill rejects reach a preset level (high level or permissive level) generally kept equal to Vessel volume.

Whenever the level probe with switches pick up, the dome valve of the Conveying System Vessel will be actuated to open to allow gravity feed of mill rejects into the conveyor vessel. After a preset time‐lapse the dome valve will be closed, insert seal will be inflated through instrument air supply.

Compressed air from dense phase conveying airline will then be injected to convey the accumulated mill reject to the storage silo via pipe work. On completion, the vessel pressure will drop down to a preset value, which will be sense by Pressure switch and the system will be reset for next cycle commencement signaled by the Level probe with switch in Pyrite Hopper.

As a back up to this, a timer provision will also be made in the control system (including the water spraying online solenoid valve). The batch cycling operation and conveying of mill rejects goes on till high level in storage silo is sensed on which further conveying to bunker is stopped till bunker is evacuated. The mode of operation is same for all mills. Operation of all the pyrite hopper pneumatic conveying system is independent of each other. The Vessels will be in operation sequentially.

RELATED SEARCHES: